The severity of impact of an oil spill depends on a variety of factors including physical characteristics of the oil and environmental conditions such as water temperature and weather. Each type of crude oil and petroleum product has distinct physical and chemical properties that will affect the way the oil will spread and breakdown, the hazard it poses to aquatic life and human health, and the threat it poses to natural resources.

Oil Spill Response

When a major spill occurs, local, state, and national personnel are called upon to help contain the spill, clean it up, and minimize damage to the environment and human health. When an oil spill first occurs, a response is initiated by the company responsible for the release, Oil Spill Response Organizations (OSROs) which are response contractors, and local first responders. If the volume of oil spills exceeds a certain amount, the company responsible for the spill is required by law to notify the National Response Center (NRC). The National Response Center (NRC) is the federal government’s national communications center, which is staffed 24 hours a day by U.S. Coast Guard (USCG) officers and marine science technicians. When the NRC receives a report of a spill, it notifies the pre-designated Federal On-Scene Coordinator (FOSC), which is the federal official who is responsible for all federal efforts in the cleanup, including coordinating with state and local entities. The FOSC is a representative of either the U.S. Coast Guard, if the spill occurs in coastal waters or the Great Lakes, or the U.S. EPA, if the spill occurs inland. The FOSC’s job is to ensure the cleanup is appropriate and timely. Under certain situations, the FOSC can take command of the cleanup from the pipeline company.

The federal government agency, either EPA or USCG, will remain involved at the site following response actions to undertake a number of activities, including assessing damages, supporting restoration efforts, recovering response costs from the parties responsible for the spill, and, if necessary, enforcing the liability and penalty provisions of the Clean Water Act, as amended by the Oil Pollution Act of 1990.

The company responsible for the oil spill has legal liability for all expenses related to containment and cleanup of oil spills as well as any damages resulting from the spill. However, when the responsible party is unknown or refuses to pay for the cleanup, funds from the Oil Spill Liability Trust Fund (OSLTF) are used. This trust fund, created in 1990, comes from an 8 cent per barrel tax on imported and domestic oil. In addition to paying for cleanup efforts, the trust fund is also used for research and development of oil spill cleanup technologies.

However, oil-sands derived crude oils are not subject to the OSLTF excise tax. The IRS conclude this based upon a 1980 House committee report which stated “the term crude oil does not include synthetic petroleum, e.g. shale oil, liquids from coal, tar sands, or biomass, or refined oil.” Several members of Congress have proposed legislation recently that would specifically include oil sands-derived crude oil within the scope of the per-barrel tax.

Clean Up Methods

There are several methods that can be used to clean up oil, depending on the type and amount of oil spilled and the environmental conditions. Some of the most commonly used methods include:

Bioremediation: Natural methods where microorganisms in the environment break down the oil or gas. This biological process can work together with other natural processes such as evaporation, oxidation, and weathering.

Booms: A temporary floating barrier used to contain an oil spill or to divert spilled oil along a desired path to making removal easier.

Skimmers: A device to recover oil by skimming it from the water surface.

Sorbents: Materials that soak up liquids and can absorb the oil.

Chemical Dispersants: Chemicals which bind to the oil causing the oil to disperse into the water diluting the oil to a concentration that is less harmful to aquatic life.

Gelling Agents: Chemicals that react with oil to make the oil harden into a solid substance.

Burning: In-situ burning involves the controlled burning of oil that has spilled from a vessel or a facility, at the location of the spill. When conducted properly, in-situ burning significantly reduces the amount of oil on the water and minimizes the adverse effect of the oil on the environment. The success of in-situ is highly dependent on a number of physical factors. Under the right environmental and oil conditions, burning can remove up to 95-98% of contained oil from the water. Human health is one of the major concerns regarding in-situ burning. Essentially, in-situ burning converts the oil from a slick on the water into airborne gases and particulates that may travel long distances and potentially come in contact with people.

Manual Recovery: Physical removal of oil, often used on shorelines and includes removal by hand with shovels, through the use of vacuum truck, pressure washing, raking, or bulldozing.

Recovered oil is either reused or disposed of by incineration or in a landfill.

The petroleum industry often characterizes crude oils according to their geographical source, but this is not a useful classification scheme for emergency responders. This classification offers little information about general toxicity, physical state, and the changes that occur with time and weathering. Therefore, spill responders classify crude oil into categories that reflect how the oils behave in a spill.

- Class A: Light, Volatile Oils – Class A oils include most refined products and many of the highest quality light crudes. These light, highly liquid, and clear oils can spread quickly on impervious surfaces and water and penetrate porous surfaces such as dirt and sand. They have a strong odor and evaporate quickly, emitting volatiles. They may be highly toxic to humans, fish, and other organisms.

- Class B: Non-Sticky Oils – Class B oils are generally non-sticky, but have a waxy or oily feel and includes medium to heavy paraffin-based oils. They are considered less toxic than Class A. As temperature rises, Class B oils are more likely to soak into surfaces and be hard to remove. When volatile components of Class B oils evaporate, the result can be Class C or Class D residue.

- Class C: Heavy, Sticky Oils – These are heavy, tarry, oils that are slow to penetrate into porous surfaces. These brown or black oils are difficult to flush away with water and density is near that of water so they often sink. Toxicity is low, but they can smother or drown wildlife. Weathering or evaporation of volatiles may produce Class D oils.

- Class D: Non-fluid Oils – Class D oils include heavy crude oils, including bitumen, and some residual and weathered oils. These non-fluid, thick oils are relatively non-toxic and don’t penetrate into porous surfaces. When heated, Class D oils may melt and coat surfaces making cleanup very difficult.

There has been recent interest and concern regarding submerged oil. This is due to the 2010 oil spill in Marshall, Michigan in which a portion of the oil sank to the bottom of the Kalamazoo River, as well as a U.S. Coast Guard Research and Development Center report stating that the Coast Guard is not capable of responding to heavy oil spills, particularly in open-water scenarios. According to the report, current methods are inadequate to find and recover submerged oil.

Oil can become submerged via two pathways. In the first pathway, an oil can be lighter than the receiving water and initially float. However, the oil can interact with sediments and subsequently become heavier than water. Depending on the amount of sediment mixed into the oil, the oil-sediment mixture can become suspended in the water column or it can sink to the bottom. In addition, lighter components of oil will evaporate to the atmosphere leaving the heavier oil that can sink. In the second pathway, an oil that is denser than the receiving water will not float.

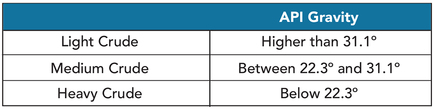

Crude oil is classified as light, medium, or heavy, which refers to the oil’s relative density based on the American Petroleum Institute (API) Gravity. The measure reflects how light or heavy a crude oil is compared to water.

There have only been a small number of submerged oils spills. From these, we have learned that there are a number of additional challenges associated with submerged oil recovery. Submerged oil is very difficult to detect, both when it is suspended in the water and sunk. Techniques that have been used to find submerged oil include divers, sonar, and water sampling. In addition to having difficulty finding the oil, there are no proven methods for containment of submerged oil, and methods for recovery of submerged oil have limited effectiveness. With increased reliance on heavier crude oils and refined products to fill the current energy demands, the proportion of oil spills involving submerged oil is also on the rise.